PREMANT district heating pipe

Tapping technology

System description

PRE 6.530

Important: Tapping technology must only be processed by specialist staff.

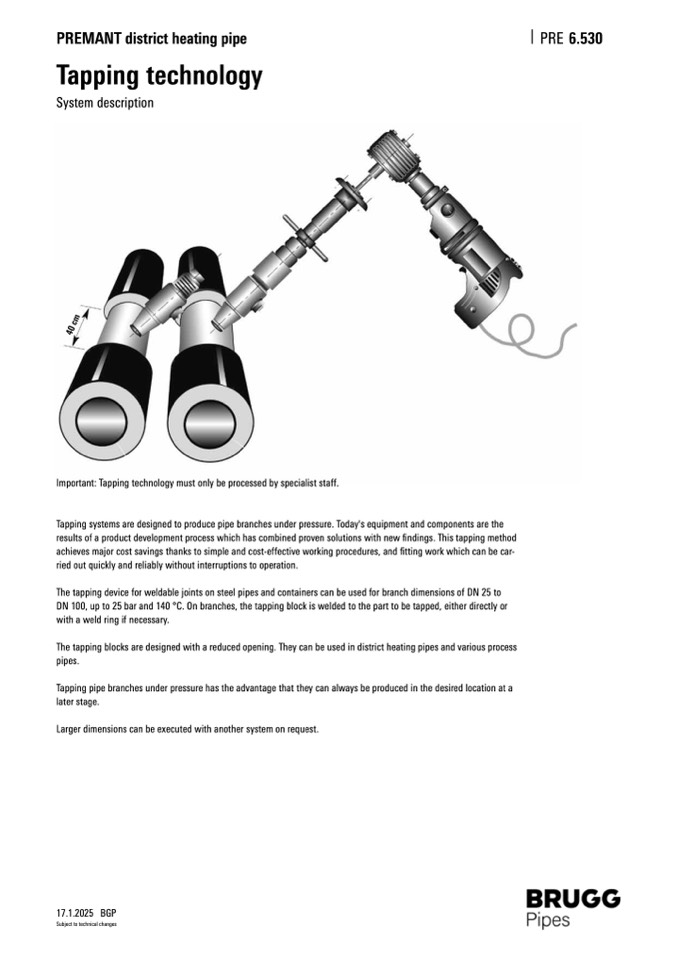

Tapping systems are designed to produce pipe branches under pressure. Today's equipment and components are the

results of a product development process which has combined proven solutions with new findings. This tapping method

achieves major cost savings thanks to simple and cost-effective working procedures, and fitting work which can be car-

ried out quickly and reliably without interruptions to operation.

The tapping device for weldable joints on steel pipes and containers can be used for branch dimensions of DN 25 to

DN 100, up to 25 bar and 140 °C. On branches, the tapping block is welded to the part to be tapped, either directly or

with a weld ring if necessary.

The tapping blocks are designed with a reduced opening. They can be used in district heating pipes and various process

pipes.

Tapping pipe branches under pressure has the advantage that they can always be produced in the desired location at a

later stage.

Larger dimensions can be executed with another system on request.

17.1.2025 BGP

Subject to technical changes

4

0

c

m