General Information

Valpres is part of the Bonomi Group that for more than 100

years has supplied valves worldwide.

Since 1978, Valpres manufactures ball valves and has been

one of the first to introduce the split body concept in the industry.

Today Valpres designs and manufactures a wide range of

high quality, manually operated or automated, on-off and

control ball valves for any kind of service in the Oil&Gas,

water, steam and power generating industry, as well as

general industry.

The basic valve design is side-entry construction (bolted or

welded). The product line is completed with a top entry design

that has the advantage to be field serviceable without

removing the valve from the line.

Side entry-bolted body and top entry valves are available with

metal or soft seats. They are also available in customized

designs suitable for non-standard services such as: highly

corrosive, lethal, SIL, cryogenic, high temperature, erosive.

Furthermore, Valpres has created and patended the VP-1

control ball valve, that handles incompressible and

compressible fluids. It is designed to handle very high flow

rates or very high differential pressure, always keeping under

control either cavitation or noise.

VP-1 valves have been integrated with the basic features of

our floating and trunnion mounted on-off ball valves.

Product line API 608

One of the Valpres most recent products are the API 608

floating ball valves.

This line have been designed and developed respecting the

requirements of the petrochemical market.

This product range implements a number of features, among

others the increased thickness and oversized driving train.

These characteristics, together with a careful choice of

materials, make these valves ideal for standard and severe

service and particularly reliable in case of actuation.

Main technical features

• Design of construction: API 608.

• Pressure and temperature range: ASME B16.34.

• Face to face dimension: ASME B16.10.

• Connections to ASME B16.5 (other ends in option).

• Tested to API 598 (other standards available in option).

• Firesafe design to API 607/ISO 10497/API 6FA.

• Anti blowout stem.

• Antistatic device.

• Soft and metal seats.

• Various extensions available (extended stem for insulation,

extended bonnet for HT, extended bonnet for LT).

• Manual and automatic operators available.

• Fugitive emission compliant (ISO 15848-1).

Materials

In stock: A352 LCB/A351 CF8M (w/SS316 trim and 17 4 PH

stem).

Made to order (cast or forged/forged bar):

• Low alloy CS for high temperature.

• Other carbon steels.

• Martensitic, austenitic, superaustenitic, duplex, superduplex

stainless steels.

• Nickel Alloys (Inconel 625, Incoloy 825, Hastelloy, Monel, etc).

• Titanium.

• Al Ni Bz.

Seats materials

• RPTFE (standard).

• Optional materials: PEEK, PCTFE, VESPEL®, metal to metal

(TCC or CCC).

Seals materials

• FKM (standard).

• Optional materials: HNBR, EPDM, FFKM, (P)VMQ, graphite.

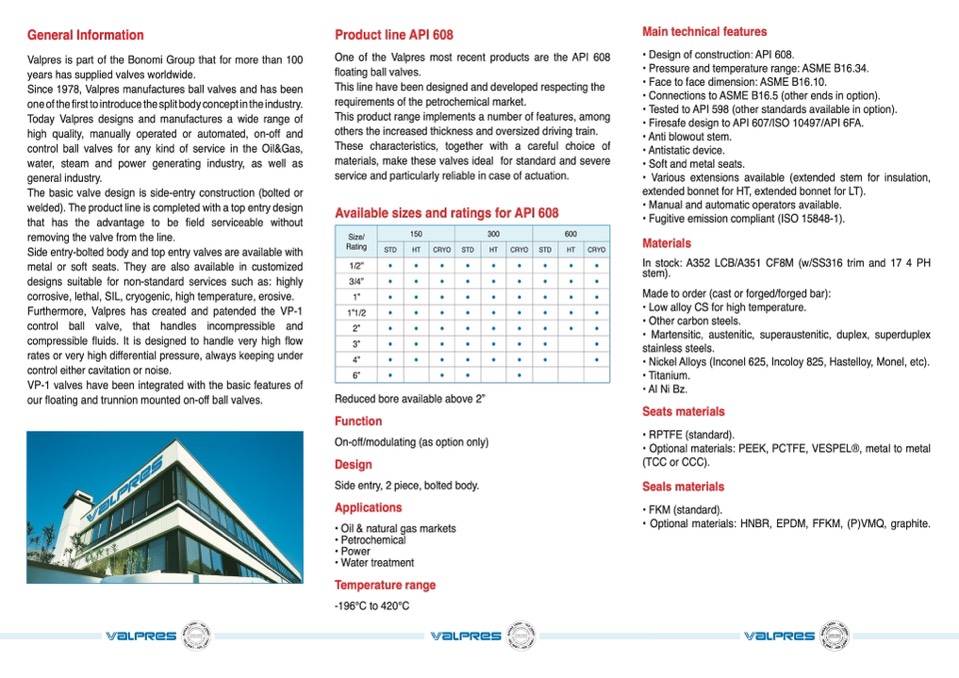

Available sizes and ratings for API 608

Size/

150

Rating

STD

HT CRYO

1/2”

• • •

3/4”

• • •

1”

• • •

1”1/2

• • •

Reduced bore available above 2”

Function

On-off/modulating (as option only)

Design

Side entry, 2 piece, bolted body.

Applications

• Oil & natural gas markets

• Petrochemical

• Power

• Water treatment

Temperature range

-196°C to 420°C

CRYO

•

•

•

•

•

•

•

2”

• • •

3”

• • •

4”

• • •

6”

•

• •

•

300

600

STD

HT CRYO STD

HT

• • • • •

• • • • •

• • • • •

• • • • •

• • • • •

• • • •

• • • •