72

Gas Governors

mAINTENANCE

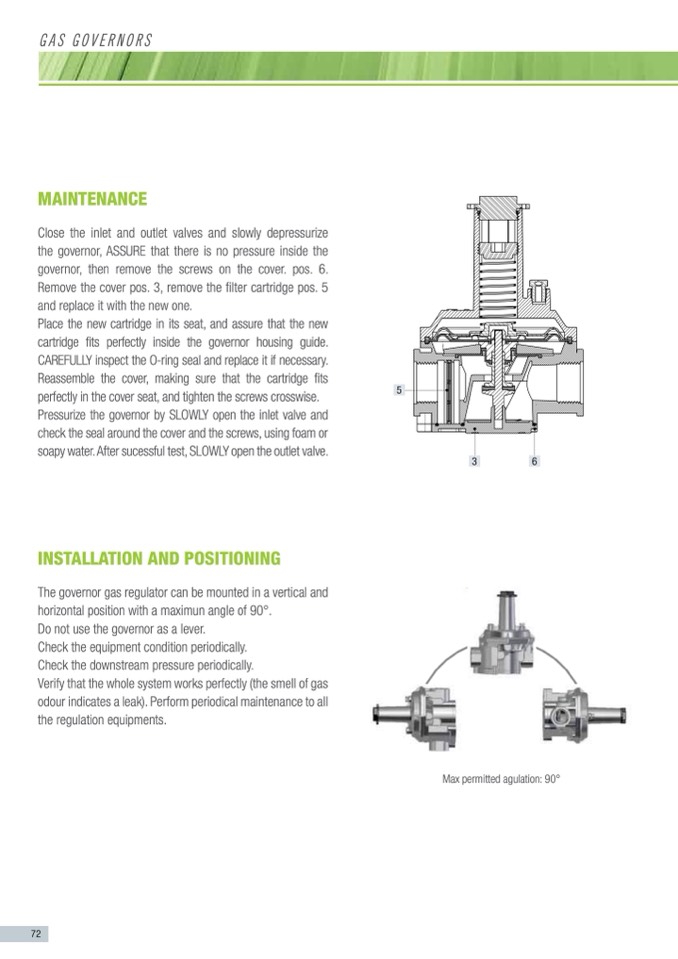

Close the inlet and outlet valves and slowly depressurize

the governor, ASSURE that there is no pressure inside the

governor, then remove the screws on the cover. pos. 6.

Remove the cover pos. 3, remove the filter cartridge pos. 5

and replace it with the new one.

Place the new cartridge in its seat, and assure that the new

cartridge fits perfectly inside the governor housing guide.

CAREFULLY inspect the O-ring seal and replace it if necessary.

Reassemble the cover, making sure that the cartridge fits

perfectly in the cover seat, and tighten the screws crosswise.

Pressurize the governor by SLOWLY open the inlet valve and

check the seal around the cover and the screws, using foam or

soapy water. After sucessful test, SLOWLY open the outlet valve.

INSTAllATION AND POSITIONING

The governor gas regulator can be mounted in a vertical and

horizontal position with a maximun angle of 90°.

Do not use the governor as a lever.

Check the equipment condition periodically.

Check the downstream pressure periodically.

Verify that the whole system works perfectly (the smell of gas

odour indicates a leak). Perform periodical maintenance to all

the regulation equipments.

5

3

6

Max permitted agulation: 90°