Storytelling

Storytelling

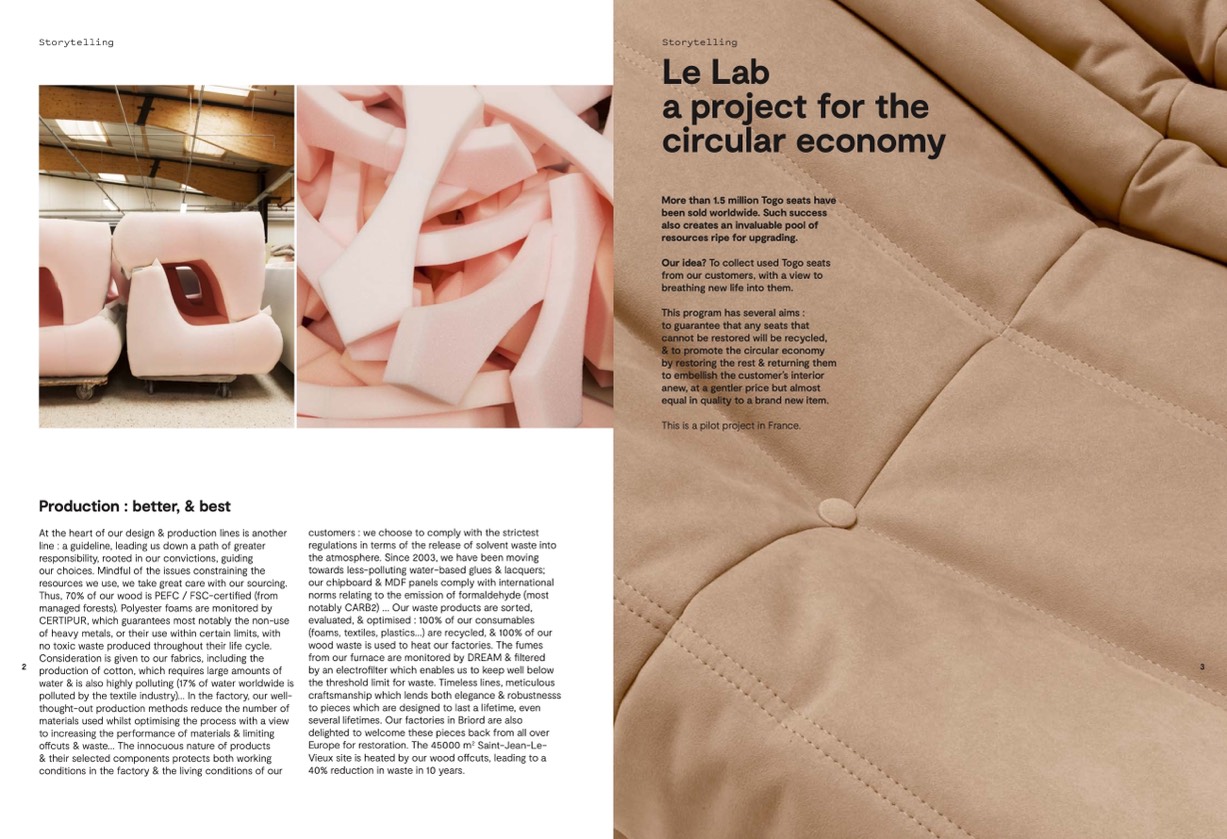

Le Lab

a project for the

circular economy

More than 1.5 million Togo seats have

been sold worldwide. Such success

also creates an invaluable pool of

resources ripe for upgrading.

Our idea? To collect used Togo seats

from our customers, with a view to

breathing new life into them.

This program has several aims :

to guarantee that any seats that

cannot be restored will be recycled,

& to promote the circular economy

by restoring the rest & returning them

to embellish the customer’s interior

anew, at a gentler price but almost

equal in quality to a brand new item.

This is a pilot project in France.

Production : better, & best

At the heart of our design & production lines is another

line : a guideline, leading us down a path of greater

responsibility, rooted in our convictions, guiding

our choices. Mindful of the issues constraining the

resources we use, we take great care with our sourcing.

Thus, 70% of our wood is PEFC / FSC-certified (from

managed forests). Polyester foams are monitored by

CERTIPUR, which guarantees most notably the non-use

of heavy metals, or their use within certain limits, with

no toxic waste produced throughout their life cycle.

2

Consideration is given to our fabrics, including the

production of cotton, which requires large amounts of

water & is also highly polluting (17% of water worldwide is

polluted by the textile industry)... In the factory, our well-

thought-out production methods reduce the number of

materials used whilst optimising the process with a view

to increasing the performance of materials & limiting

offcuts & waste... The innocuous nature of products

& their selected components protects both working

conditions in the factory & the living conditions of our

customers : we choose to comply with the strictest

regulations in terms of the release of solvent waste into

the atmosphere. Since 2003, we have been moving

towards less-polluting water-based glues & lacquers;

our chipboard & MDF panels comply with international

norms relating to the emission of formaldehyde (most

notably CARB2) ... Our waste products are sorted,

evaluated, & optimised : 100% of our consumables

(foams, textiles, plastics...) are recycled, & 100% of our

wood waste is used to heat our factories. The fumes

from our furnace are monitored by DREAM & filtered

by an electrofilter which enables us to keep well below

the threshold limit for waste. Timeless lines, meticulous

craftsmanship which lends both elegance & robustnesss

to pieces which are designed to last a lifetime, even

several lifetimes. Our factories in Briord are also

delighted to welcome these pieces back from all over

Europe for restoration. The 45000 m

2

Saint-Jean-Le-

Vieux site is heated by our wood offcuts, leading to a

40% reduction in waste in 10 years.

3