Technical details

FSR 4.413

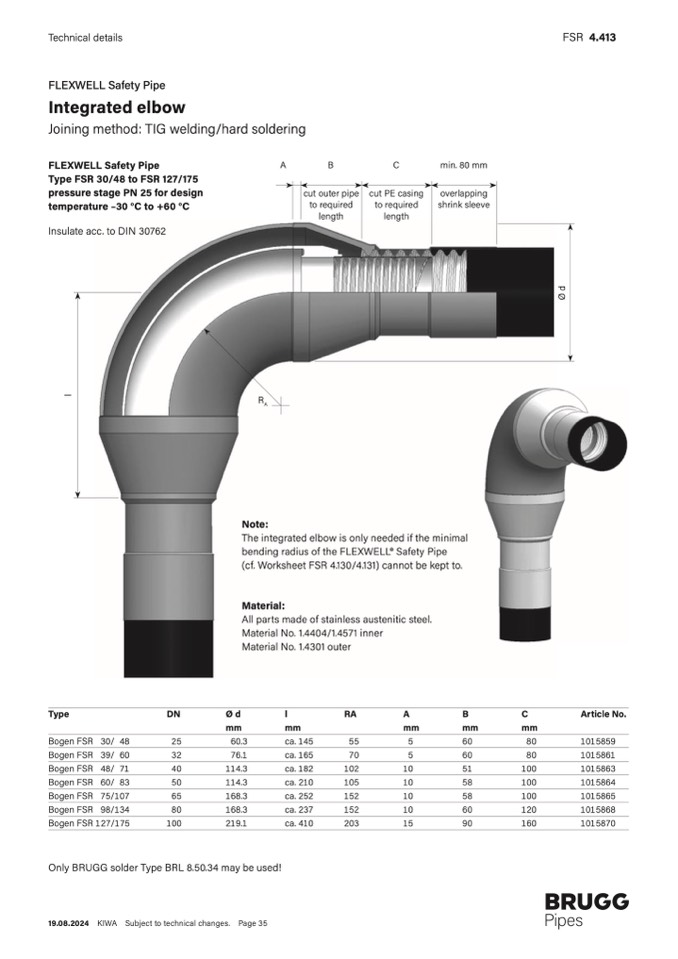

FLEXWELL Safety Pipe

Integrated elbow

Joining method: TIG welding/hard soldering

FLEXWELL Safety Pipe

Type FSR 30/48 to FSR 127/175

pressure stage PN 25 for design

temperature –30 °C to +60 °C

Insulate acc. to DIN 30762

A

B

cut outer pipe

to required

length

C

cut PE casing

to required

length

min. 80 mm

overlapping

shrink sleeve

Type

DN

Ød

l

mm

mm

60.3

ca. 145

76.1

ca. 165

114.3

ca. 182

114.3

ca. 210

168.3

ca. 252

168.3

ca. 237

219.1

ca. 410

RA

A

B

C

m

m

m

m

mm

ArticleNo.

1015859

1015861

1015863

1015864

1015865

1015868

1015870

Bogen FSR 30/ 48

Bogen FSR 39/ 60

Bogen FSR 48/ 71

Bogen FSR 60/ 83

Bogen FSR 75/107

Bogen FSR 98/134

Bogen FSR 127/175

25

32

40

50

65

80

55

5

70

5

102

10

105

10

152

10

152

10

203

15

60

80

60

80

51

100

58

100

58

100

60

120

90

160

100

Only BRUGG solder Type BRL 8.50.34 may be used!

19.08.2024 KIWA Subject to technical changes. Page 35

R

A

Note:

The integrated elbow is only needed if the minimal

bending radius of the FLEXWELL® Safety Pipe

(cf. Worksheet FSR 4.130/4.131) cannot be kept to.

Material:

All parts made of stainless austenitic steel.

Material No. 1.4404/1.4571 inner

Material No. 1.4301 outer

l

Ø

d