PRODUCT GUIDE

RAK CERAMICS | FALL WINTER COLLECTION 2022

TECHNICAL FEATURES

GRES WHITE BODY TILES (BIIA) :

Gres white body tiles are created by mixing raw materials including high quality white or red clays, quartz and feldspar

in wet grinding ball mills. After grinding, a clay-based suspension of these materials called a slip is fed out of the mill

then spray-dried to remove excess moisture. Following the spray drying process, the free flowing powder is pressed

using advanced hydraulic presses with a speci

fic pressing power exceeding 300 kg/cm2 in order to obtain a compact

gres body. Once dried, the tiles are coated and decorated with glazes to make them aesthetically pleasing and meet

our customers design requirements.

The glazed tile body is then fired in roller kilns where temperatures of approximately 1200 °C are reached. The resulting

product is normally a medium-to-low porosity (3% to 5%) tile, in compliance with the International Standard ISO 13006

and European Standard UNI EN 14411 standard and rated as belonging to the BIIa GL group with notable technological

specifications such as the product flexural strength (average value: 30N/mm2 according to UNI EN ISO 10545-4).

As for wear resistance, this will depend on the type and colour of glazing and may change according to different

products or collections. As a general rule, bright finishes are not recommended for heavy traffic floors or rooms

opening onto outdoor areas, where sand or other abrasive materials are more likely to be brought in.

ADVICE ON LAYING

Our gres white body tiles can be laid using either traditional cement mortar or modern tile adhesives. When laying

large size tiles, it is best to adopt the two-layer spreading system to ensure the adhesive is spread over 90 % of the

tile surface.

Quickly dipping each tile in water before installation will remove any dust on the back of the tile for perfect adhesion,

however, do not wet the tiles if you are using vinyl, acrylic resin adhesives or two-component organic-solvent based

adhesive.

It is advisable to always incorporate suitable shrinkage-flexion joints (movement/expansion joints) which must not

be spaced more than 4-5 metres apart from one another. These joints must be inserted not only between the tiles,

but also reach the levelling compound below, consisting of either cement mortar or dry compound, depending on

whether the tiles are set in the traditional manner or using a modern adhesive. The movement joints must be sealed

with appropriate materials such as silicone or polyurethane-based sealants, depending on the anticipated traffic of

the application area.

Appropriate tile bedding layers should be used such as underlay, damp course, vapour barrier or any other layer

necessary to prevent the tiles from detaching themselves or cracking due to water penetration.

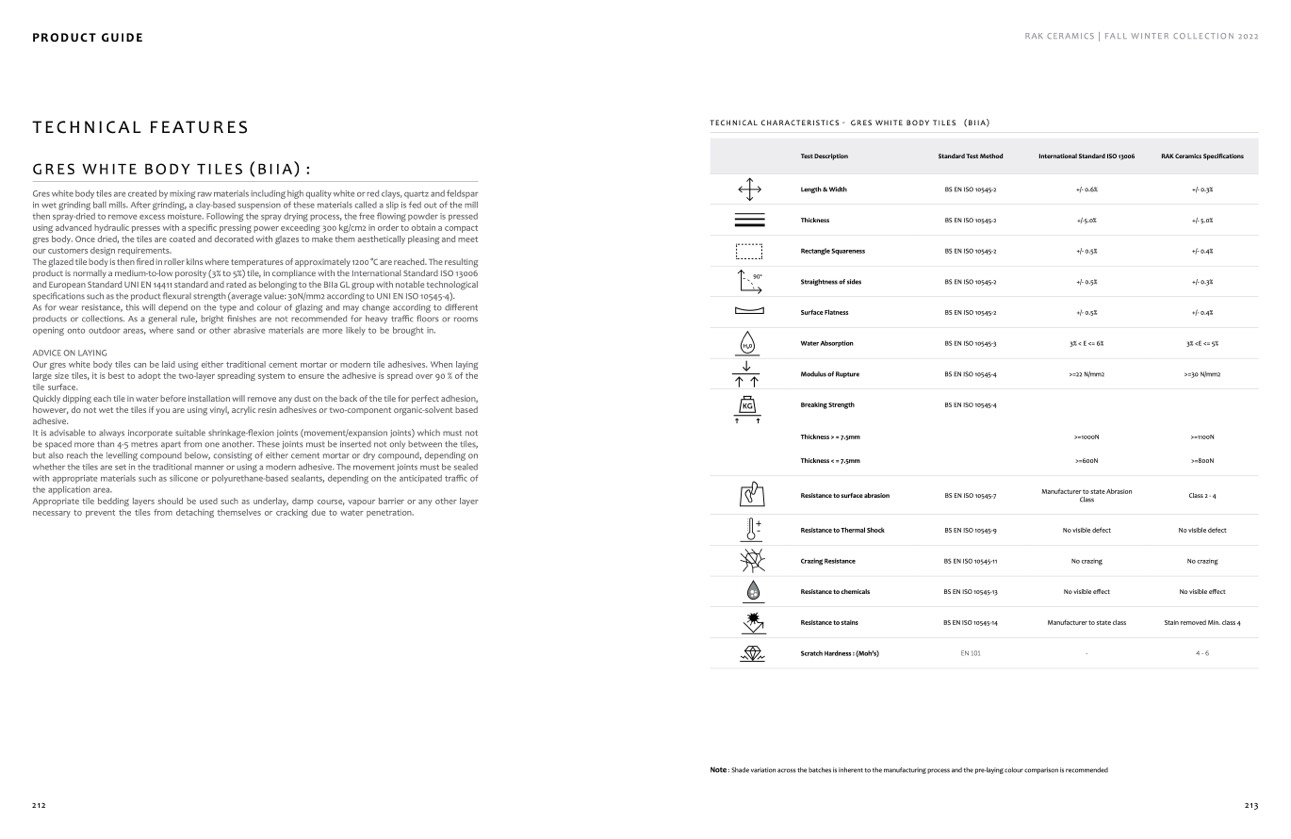

TECHNICAL CHARACTERISTICS - GRES WHITE BODY TILES (BIIA)

Test Description

Standard Test Method

International Standard ISO 13006

RAK Ceramics Specifications

Length & Width

Thickness

Rectangle Squareness

Straightness of sides

Surface Flatness

Water Absorption

Modulus of Rupture

Breaking Strength

Thickness > = 7.5mm

Thickness < = 7.5mm

Resistance to surface abrasion

Resistance to Thermal Shock

Crazing Resistance

Resistance to chemicals

Resistance to stains

Scratch Hardness : (Moh’s)

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-3

BS EN ISO 10545-4

BS EN ISO 10545-4

BS EN ISO 10545-7

BS EN ISO 10545-9

BS EN ISO 10545-11

BS EN ISO 10545-13

BS EN ISO 10545-14

EN 101

+/- 0.6%

+/-5.0%

+/- 0.5%

+/- 0.5%

+/- 0.5%

3% < E <= 6%

>=22 N/mm2

>=1000N

>=600N

Manufacturer to state Abrasion

Class

No visible defect

No crazing

No visible effect

Manufacturer to state class

-

+/- 0.3%

+/- 5.0%

+/- 0.4%

+/- 0.3%

+/- 0.4%

3% <E <= 5%

>=30 N/mm2

>=1100N

>=800N

Class 2 - 4

No visible defect

No crazing

No visible effect

Stain removed Min. class 4

4 - 6

212

213

Note : Shade variation across the batches is inherent to the manufacturing process and the pre-laying colour comparison is recommended