PREMANT district heating pipe

PRE 6.365

Expansion pad

Description

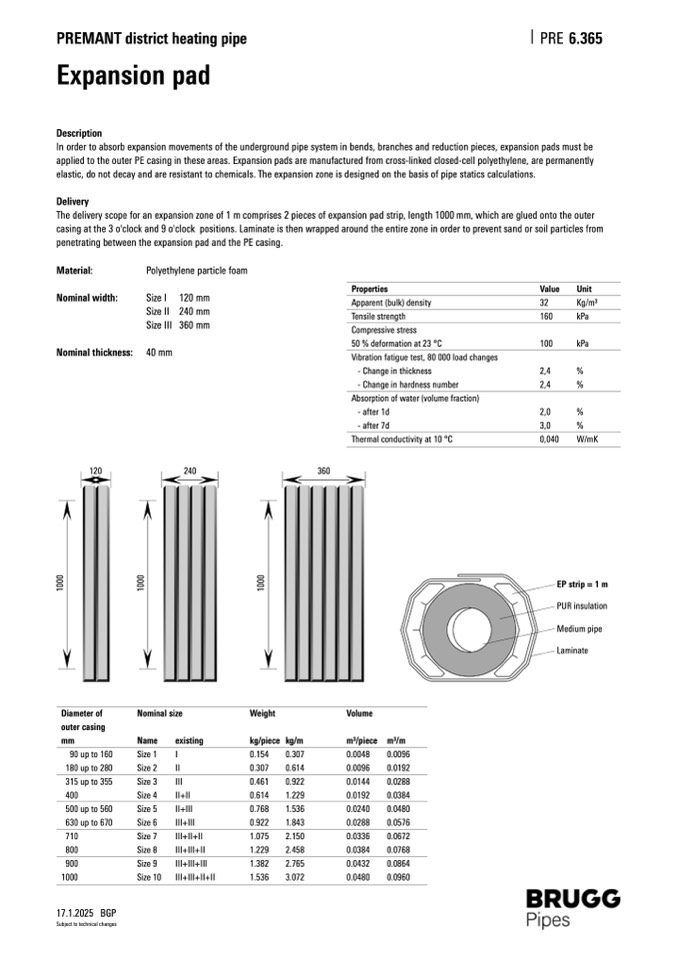

In order to absorb expansion movements of the underground pipe system in bends, branches and reduction pieces, expansion pads must be

applied to the outer PE casing in these areas. Expansion pads are manufactured from cross-linked closed-cell polyethylene, are permanently

elastic, do not decay and are resistant to chemicals. The expansion zone is designed on the basis of pipe statics calculations.

Delivery

The delivery scope for an expansion zone of 1 m comprises 2 pieces of expansion pad strip, length 1000 mm, which are glued onto the outer

casing at the 3 o'clock and 9 o'clock positions. Laminate is then wrapped around the entire zone in order to prevent sand or soil particles from

penetrating between the expansion pad and the PE casing.

Material:

Nominal width:

Nominal thickness:

120

Polyethylene particle foam

Diameter of

outer casing

mm

90 up to 160

180 up to 280

315 up to 355

400

500 up to 560

630 up to 670

710

800

900

1000

17.1.2025 BGP

Subject to technical changes

Nominal size

Weight

kg/piece kg/m

0.154

0.307

0.307

0.614

0.461

0.922

0.614

1.229

0.768

1.536

0.922

1.843

1.075

2.150

1.229

2.458

1.382

2.765

1.536

3.072

Volume

m3/piece m3/m

0.0048

0.0096

0.0096

0.0192

0.0144

0.0288

0.0192

0.0384

0.0240

0.0480

0.0288

0.0576

0.0336

0.0672

0.0384

0.0768

0.0432

0.0864

0.0480

0.0960

Size I

Size II

Size III

40 mm

120 mm

240 mm

360 mm

Properties

Apparent (bulk) density

Tensile strength

Compressive stress

50 % deformation at 23 °C

Vibration fatigue test, 80 000 load changes

- Change in thickness

- Change in hardness number

Absorption of water (volume fraction)

- after 1d

- after 7d

Thermal conductivity at 10 °C

Value

Unit

32

Kg/m3

160

kPa

100

kPa

2,4

%

2,4

%

2,0

%

3,0

%

0,040

W/mK

EP strip = 1 m

PUR insulation

Medium pipe

Laminate

Name

Size 1

Size 2

Size 3

Size 4

Size 5

Size 6

Size 7

Size 8

Size 9

Size 10

existing

I

II

III

II+II

II+III

III+III

III+II+II

III+III+II

III+III+III

III+III+II+II

240

360

1

0

0

0

1

0

0

0

1

0

0

0