GAS VALVES

PENING

1

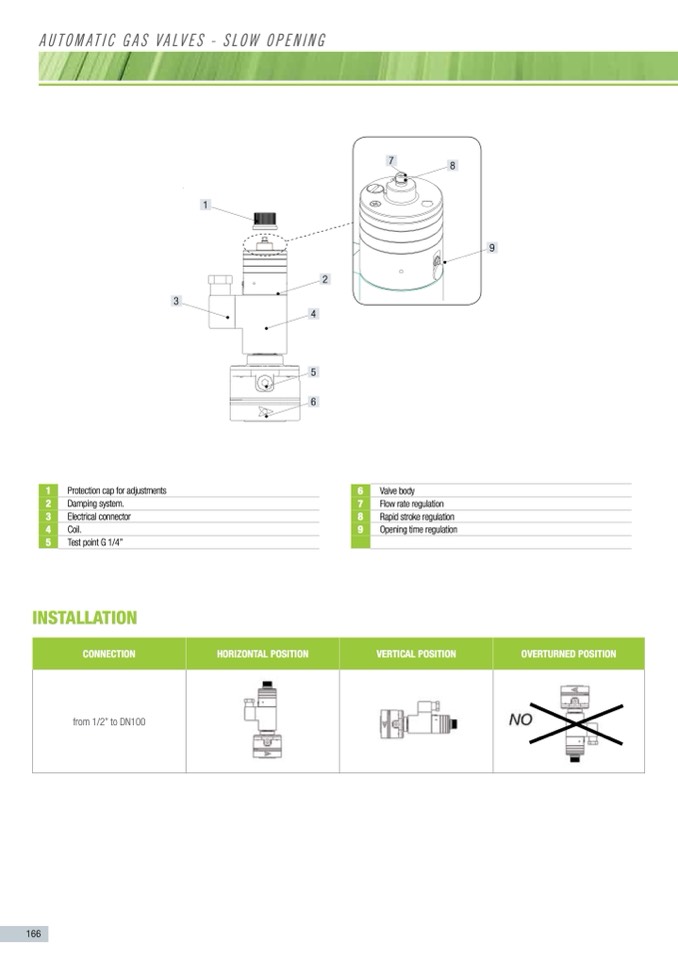

Protection cap for adjustments.

2

Damping system.

3

Electrical connector

4

Coil.

5

Test point G 1/4”.

6

Valve body.

7

Flow rate regulation.

8

Rapid stroke regulation.

9

Opening time regulation.

O

PENING

1

5-SO

2

3

2

4

5

6

230V

C1+

C 2-

e

n

sions:

=

1/2”

=

3/4”

=

1”

SO=Slow Opening

1

Protection cap for adjustments

2

Damping system.

3

Electrical connector

4

Coil.

5

Test point G 1/4”

Identification symbol of the “rectifier”

connectors. (see table coil marking)

D

ESCRIPTION

Clockwise

HorIzonTal posITIon

Clockwise

aUToMaTIC Gas vaLves - sLow openInG

INSTAllATION

and normally closed.

G

allow the regulation of:

connEcTIon

o

pen when the coil is powered and close

M

OVE THE DAMPING SYSTEM WITH

from 1/2” to DN100

I

ON VALVES

f

ore installation.

o

w facing towards the user appliance.

a

llow debris or scraps of metal to enter

o

t more then max pressure of the valve.

h

e coil voltage.

s

-tight after installation.

166

oVErTurnED posITIon

must be carried out only by qualified

English

1

3

9

6

7

8

9

Valve body

Flow rate regulation

Rapid stroke regulation

Opening time regulation

Counter clockwise

VErTIcal posITIon

Counter clockwise

7

8