TACOCONTROL Z1 S

Commissioning and operation

6

Commissioning and operation

When commissioning, the parameters have already been set at

the factory (

Ä Chapter 7 ‘Parameter settings and display values’

on page 26) and can be changed on the HMI ( Ä Chapter 6.2.1

‘Setting parameters on the HMI’ on page 24).

NOTICE!

Damage to the pump due to dry operation!

The controller is a component of the heat interface

unit. The controller and the heat interface unit draw

energy from the same connector. If the controller is

connected to the mains power before filling the heat

interface unit, then the pumps operate dry and will

be damaged.

– Fill the heat interface unit before connecting the

controller to the mains power.

6.1 Connecting the HMI

Personnel:

n Operator

n Heating and sanitary technician

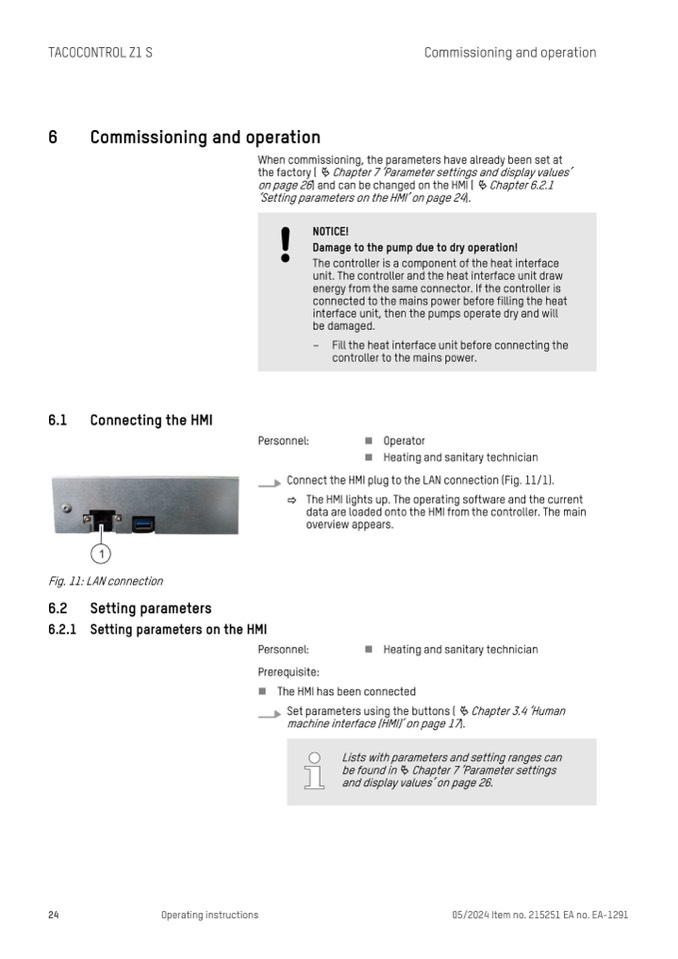

Connect the HMI plug to the LAN connection (Fig. 11/1).

ð The HMI lights up. The operating software and the current

data are loaded onto the HMI from the controller. The main

overview appears.

Fig. 11: LAN connection

6.2

6.2.1

Setting parameters

Setting parameters on the HMI

Personnel:

n Heating and sanitary technician

Prerequisite:

n The HMI has been connected

Set parameters using the buttons (

Ä Chapter 3.4 ‘Human

machine interface (HMI)’ on page 17).

24

Operating instructions

05/2024 Item no. 215251 EA no. EA-1291

Lists with parameters and setting ranges can

be found in

Ä Chapter 7 ‘Parameter settings

and display values’ on page 26.