Instructions for Laying

FSR 8.70.02

FLEXWELL Safety Pipe

Instructions for laying and mounting FLEXWELL Safety piping

FSR DN 12 – DN 150

Make sure that the ends of the pipes have been sealed so

that no foreign bodies can find their way into them.

Store the piping at a temporary interim storage position

before proceeding to laying.

3 Determining the lengths and laying the piping

Determining the length of the pipes: before measuring out

the pipe lengths, number the entries to the filling shaft and

the through-connections at the corresponding manhole

shaft. Then transfer these numbers to the piping routing

plan (e.g.: 1, 2, 3 etc.). To determine the length, e.g. of the

filling lines, lay a tape measure from connection 1 of the

filling shaft along the route of the intended pipe run with

the laying radii of the piping to the connection 1 of each

manhole cover. Repeat this procedure at the other filling

shaft connections. Note down the lengths and add them

together. Is the piping which has been delivered long

enough for the actual pipe run to be laid?

If the piping has been protected during transport by means

of shuttering boards, these must be removed before laying

using tools such as crowbars, hammers etc. Make abso-

lutely sure when doing this that the piping underneath

the boards is not damaged. The boards should only be

removed directly prior to laying the piping, however, to

prevent any unforeseen damage to the piping.

Another conceivable option is to set up a stationary un-

winding device using a DN 100 – DN 125 steel pipe as the

axle for the drum.

Another widely used method employs transportable drum

stands with a hydraulic lifting device. With this, a rigid axle

is passed through the drum as in the method described

above. The drum is then lifted using the lifting device.

To pull the piping off, use the loops normally available in

the trade (50 mm wide, 2 m long) or similar (ropes etc.).

Warning! Danger of injury!

Before pulling off the loose end of the pipe from the

drum, hold it very tight with these loops and only

then cut the straps fastening it to the drum using a

knife. During this, two men should hold the pipe still

and one man should take care of braking the move-

ment of the drum.

After pulling off, draw the piping towards the trench. Always

take care while doing this that no sand or other dirt can

get into the inside of the piping (hold up the pipe end). Pull

the pipe off the drum slowly and carefully, making sure that

it is not damaged by sharp edges during pulling-off. If the

pulling-off process is interrupted, the drum must also be

braked to stop it continuing to turn (coil spring effect).

Attention:

!

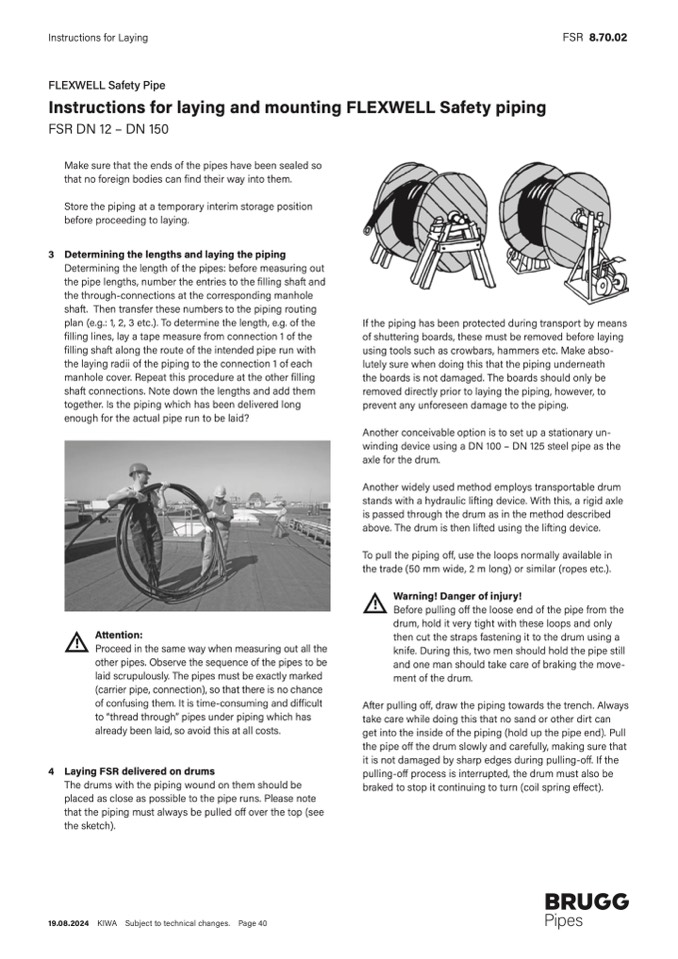

4 Laying FSR delivered on drums

The drums with the piping wound on them should be

placed as close as possible to the pipe runs. Please note

that the piping must always be pulled off over the top (see

the sketch).

Proceed in the same way when measuring out all the

other pipes. Observe the sequence of the pipes to be

laid scrupulously. The pipes must be exactly marked

(carrier pipe, connection), so that there is no chance

of confusing them. It is time-consuming and difficult

to “thread through” pipes under piping which has

already been laid, so avoid this at all costs.

19.08.2024 KIWA Subject to technical changes. Page 40

!