Instructions for Laying

FSR 8.70.03

FLEXWELL Safety Pipe

Instructions for laying and mounting FLEXWELL Safety piping

FSR DN 12 – DN 150

!

Warning! Danger of injury!

The piping has an angular momentum after

pulling-off which is released immediately after

it is sawn through.

The ends, which are now open and exposed, must be pro-

tected against dirt and contamination by means of placing

bags or caps over them. Using a white marker or other

similar means of designation (carrier pipe, connection),

mark them clearly. Place the piping where it will be in-

stalled later on.

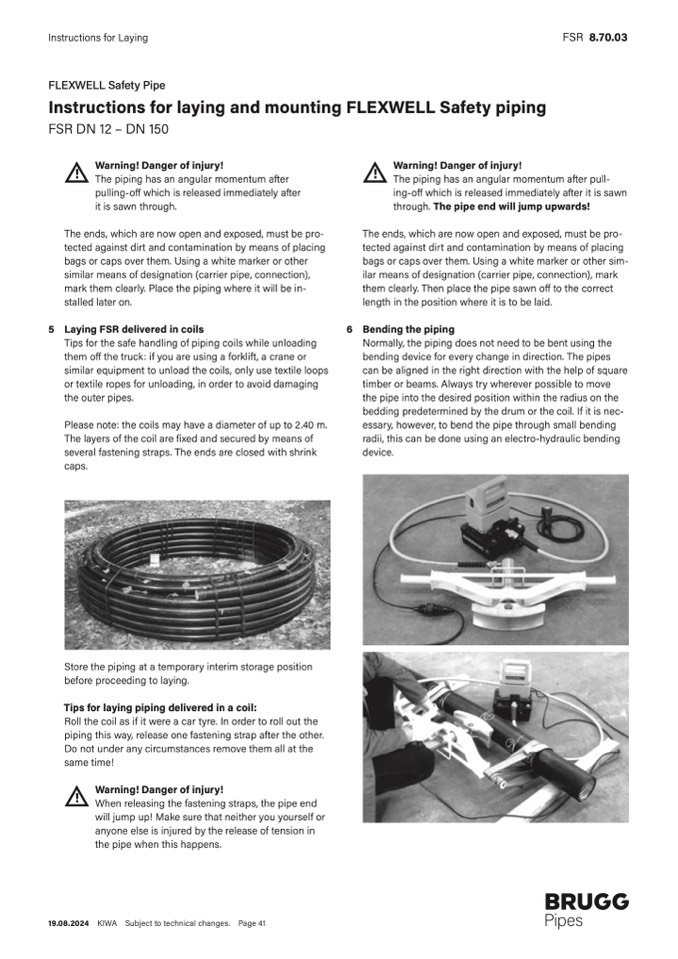

5 Laying FSR delivered in coils

Tips for the safe handling of piping coils while unloading

them off the truck: if you are using a forklift, a crane or

similar equipment to unload the coils, only use textile loops

or textile ropes for unloading, in order to avoid damaging

the outer pipes.

Please note: the coils may have a diameter of up to 2.40 m.

The layers of the coil are fixed and secured by means of

several fastening straps. The ends are closed with shrink

caps.

Store the piping at a temporary interim storage position

before proceeding to laying.

Tips for laying piping delivered in a coil:

Roll the coil as if it were a car tyre. In order to roll out the

piping this way, release one fastening strap after the other.

Do not under any circumstances remove them all at the

same time!

Warning! Danger of injury!

When releasing the fastening straps, the pipe end

will jump up! Make sure that neither you yourself or

anyone else is injured by the release of tension in

the pipe when this happens.

!

Warning! Danger of injury!

The piping has an angular momentum after pull-

ing-off which is released immediately after it is sawn

through. The pipe end will jump upwards!

The ends, which are now open and exposed, must be pro-

tected against dirt and contamination by means of placing

bags or caps over them. Using a white marker or other sim-

ilar means of designation (carrier pipe, connection), mark

them clearly. Then place the pipe sawn off to the correct

length in the position where it is to be laid.

6 Bending the piping

Normally, the piping does not need to be bent using the

bending device for every change in direction. The pipes

can be aligned in the right direction with the help of square

timber or beams. Always try wherever possible to move

the pipe into the desired position within the radius on the

bedding predetermined by the drum or the coil. If it is nec-

essary, however, to bend the pipe through small bending

radii, this can be done using an electro-hydraulic bending

device.

19.08.2024

KIWA Subject to technical changes. Page 41

!